Amongst the new items: tube connector with ball joint and linear actuators with Omega drive

RK Rose+Krieger at Motek 2018

Just in time for Motek 2018, RK Rose+Krieger is ready with numerous innovations in linear and tube connecting technology. Alongside the four new Solid Clamp variants with ball joint, with the RK Monoline MT, the specialists for linear, profile, connecting and modular technology are showing a new linear unit with Omega drive, and the newest member of the product family of EP(X) II twin-tube units – the EP(X) II KG with ball screw drive. The new RK Monoline Z 60 and the Multilift Controll II lifting column and electric cylinder controller will also be presented.

The tube connectors with ball joint provide even more freedom for tube constructions – a flexible alternative to welded constructions

Solid Clamps with ball joint – four new models for even more flexibility

The product family of aluminium Solid Clamp tube connectors has a new addition: size 30 base clamps, sleeve clamps and hinge clamps are now also available for delivery with integrated ball joint. A sleeve clamp with double ball also adds to the range. The ball joints are designed for loads of up to 40 Nm (static). Connected applications can be pivoted freely by 60° and rotated freely by 360°. This way, the new tube connectors with ball joint provide a significantly higher degree of freedom for construction than conventional hinged connectors. An appropriate surface coating on the ball joint makes for a high-strength clamping connection. The clamps feature a universal connecting plate for flexible integration.

EP(X) II KG – twin-tube linear actuator with ball screw drive

The new high-precision linear unit with polished solid shafts and ball linings is the successor to the tried-and-tested COPAS actuator from RK Rose+Krieger. The EP(X) II KG is suitable for dynamic movement and precise positioning of medium to high loads in any installed position in continuous operation. Adjustment is preferably performed with servomotors. When doing so, almost all types from any number of manufacturers can be adapted.

The functional dimensions of the new unit, which compensates high bending moments, have been adapted to those of the EP(X) product line. This facilitates free combination with any other actuators and the entire range of accessories from the line. The EP(X) II KG Protect version of the new linear unit can be equipped with optional bellows to protect the actuator. It thus achieves protection class IP 40.

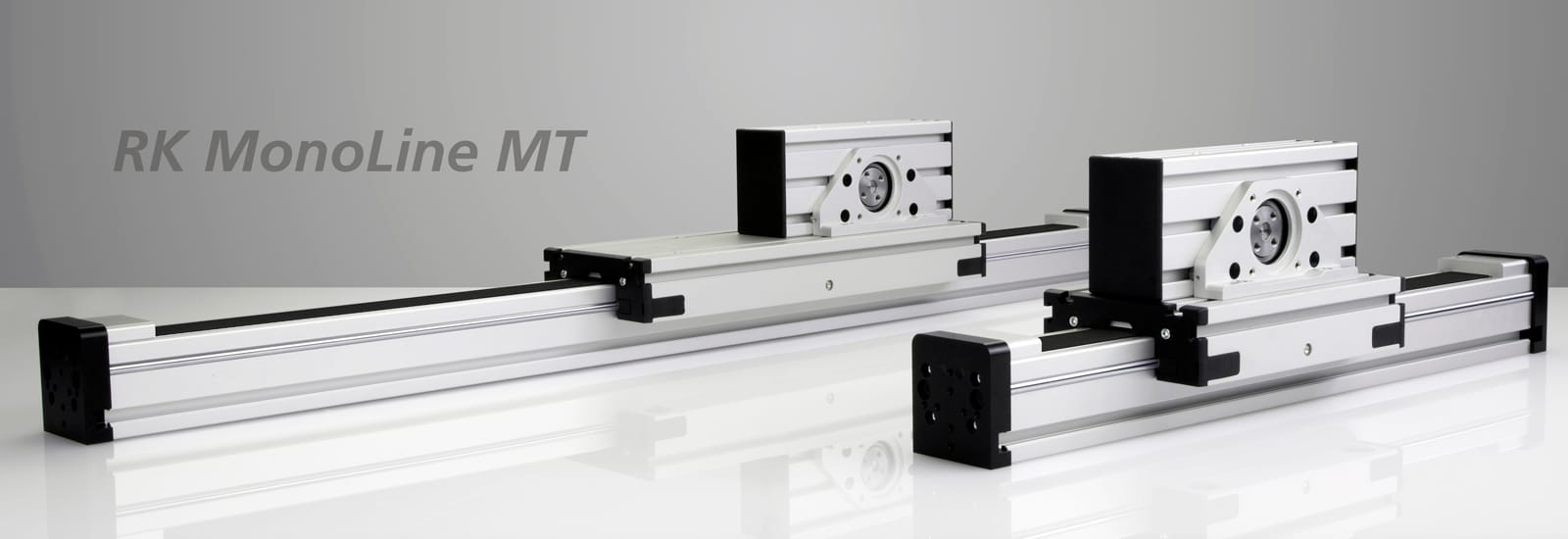

The new member of the RK Monoline product line is based on the roller guide concept of the RK MonoLine Z 80

RK Monoline MT – linear unit with Omega drive

The new member of the RK Monoline product line is based on the roller guide concept of the RK MonoLine Z 80, but has a different drive concept: on the RK Monline MT, the timing belt does not circulate, but is driven in the area of the guide carriage. That is why an Omega drive is referred to. The tried-and-tested variable mounting concept allows the motor position to be changed subsequently for almost all motors available on the market. Compact dimensions facilitate high speeds and high positioning accuracy and repeatability – in particular for use as a vertical axis in a multi-axis system with travelling base profile and stationary carriage/motor. As a horizontal axis with a rated load on the carriage, on the other hand, extremely long strokes can be achieved. A further typical application is use as a moving axis.

RK Monoline Z 60 – Range extended to include new size

The RK Monoline range of roller guides with timing belt drives has been extended to include size 60. The four standard sizes 40, 60, 80 and 120 are now available. The variable mounting concept for the linear units is suitable for virtually all motors and enables the subsequent modification of the position of the motor. Profile slots reduce the amount of engineering required to fix rated loads and make customisation easier. The RK MonoLine Z can withstand loads of up to 2,800 N, reaches travel speeds of up to 10 m/s with permissible accelerations of up to max. 20 ms², and represents excellent value for money.

MultiControl II – New controller generation for linear drives

RK Rose+Krieger is currently reworking the most part of its range in the field of lifting columns and electric cylinders. The goal: alongside the Multilift II product line, further drives are also to be compatible for operation with the new MultiControl II controller. The controller has numerous benefits: it facilitates network connection of up to eight controllers with each other and thus synchronous activation of up to 16 drives. A duty cycle, overcurrent and temperature monitoring function, included as standard, also make for high processing reliability. A high-performance, extremely energy-efficient switching power supply with wide range input makes worldwide use possible. The MulitControl II can be operated intuitively using a hand switch with graphic display, and can also be integrated into master control system levels thanks to industrial interfaces.

Visit RK Rose+Krieger at Motek in Stuttgart, Germany – 08-11 October 2018, Hall 4, Stand 4410/4411.