What is a pick to light system and how does it work?

Pick to light (other terms with the same meaning pick by light and Pick 2 light (P2L) are often used) is a display system for defect-free packaging and order picking which is now also being introduced into the assembly process in order to ensure flawless configuration and assembly of machine parts or components.

The basis for a pick to light system is the display above the material being picked and an acknowledgement function once the material has been picked.

The SETAGO® system features a display above the material which also functions as a sensor which introduces the next process step when triggered, or stops the process or issues a signal when a mistake is made.

There are a large number of suppliers of pick to light modules on the market. Given the complexity caused by individual production requirements (individual processes, in-house solutions, varying workstation organisation etc.), it is often not so easy to find a suitable solution.

- The SETAGO® pick to light system sets itself apart from other P2L assistance systems on the market thanks to its excellent simplicity in three essential aspects.

- 1. Installation – so smart!

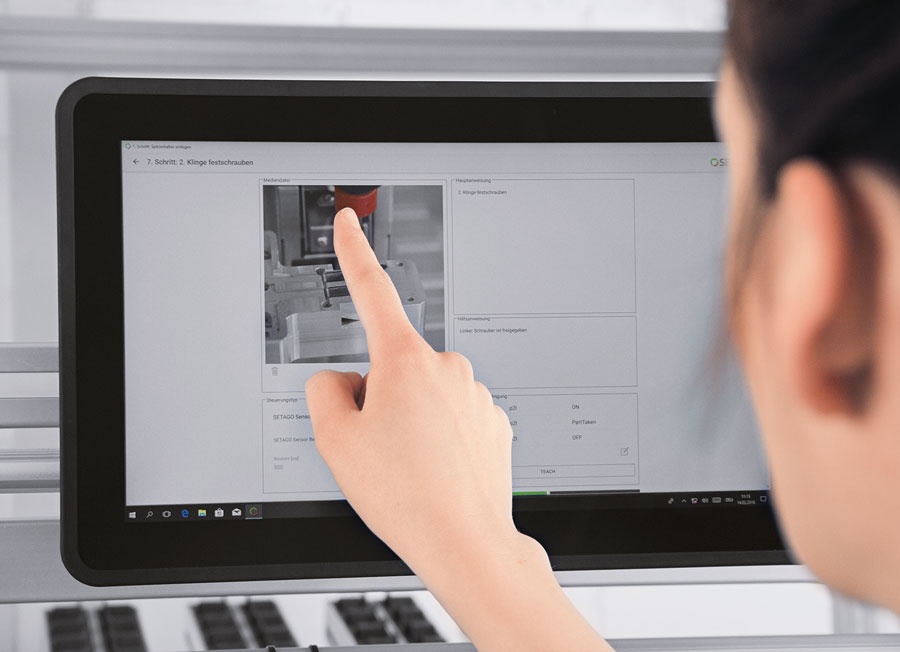

New adapter plates and click fasteners make installation of the sensors easy - 2. Commissioning – so fast!

Setting up the production processes is intuitive and quick, meaning that you can get started promptly - 3. Use – it's never been so simple!

Working with the SETAGO is so simple that absolutely anyone can follow assembly processes. Give it a try!

Benefit from the advantages of the SETAGO pick to light system

- The benefits of the SETAGO pick to light assistance system at a glance:

- Zero defects!

- Higher productivity!

- Process reliability even with multiple product variants!

- New employees are trained and productive within a few minutes!

- Consistent quality regardless of the employee!

- Simple installation and commissioning!

- Amortisation within a few months!

- Paper-free assembly instructions!

- Employees requiring support can assemble more complex products!

It does not matter which employee/worker is carrying out manual assembly, SETAGO® guarantees consistent process quality and the certainty that defects will no longer occur within the production process. New employees are guided by images and videos and are able to work productively and defect-free within a short space of time. This makes for more flexibility in personnel planning and counteracts the lack of qualified specialists. A pick to light system also allows cognitively impaired employees to produce more complex jobs. Working sequences can be completed very easily using imported parts lists, and provide a digital replacement for yellowing and often outdated sets of assembly instructions on paper. Ultimately the SETAGO pick to light system amortises within a few months thanks to increased productivity and the elimination of costs for correcting defects.

SETAGO guides you step by step through the assembly process with images and videos. The SETAGO sensor immediately signals when incorrect parts are picked or if an incorrect torque is used. The assembly process cannot continue until the error has been corrected.

Errors are ruled out, the quality of your product is ensured and your productivity also increases (zero defect strategy).

SETAGO Pick2Light is particularly beneficial when you have a large range of product variants: new employees hardly require any training time and are productive immediately. This also goes for complicated and complex working steps.

Thanks to an increase in productivity with better quality and zero defects, the SETAGO pick to light assistance system can be amortised in just a few months.

Our service – expert consultation also available on-site

SETAGO® is a brand name for a pick-by-light worker assistance system developed by Phoenix Mecano Solutions AG and Setago.io GmbH. We are of course in close contact with the resident product specialists there when it comes to detailed issues, and we develop the perfectly tailored solution for your processes together with you.

- We assist you from the first review right through to commissioning – your partner for process optimisation!

- Field service – on-site consultation also available

- Our Key Account managers and sales consultants are happy to visit you on site and help you draw up practical solutions.

- Just make a sketch of your requirements

- Workshop – definition of the required components

- Our product specialists will devise a solution for you

- Implementation and delivery

We can deliver your turnkey solution or assemble and commission it for you on site.

Always the right contact

Your contact at RK ROSE+KRIEGER:

Olaf Durstewitz

Head of Product Consultancy