Connecting tubes easily without annoying transitions

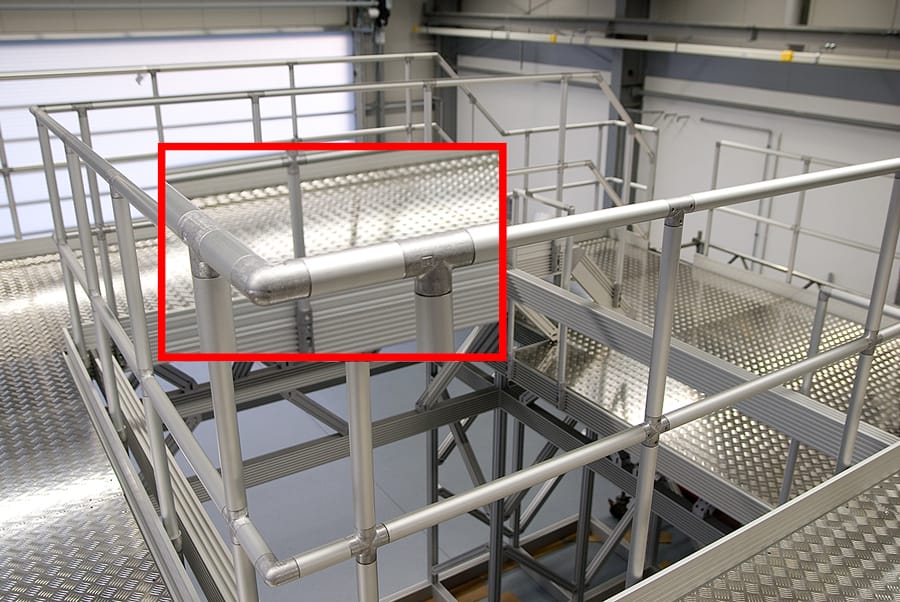

The industrial stairs and working platform system (ITAS) is a real all-rounder: It provides a technically reliable solution for railings, boundaries, pedestals, stairs, crossovers and working platforms, all without the need for welding. The facilities created can be dismantled or varied at any time. With a modification to the standard product, the flexible system can even be used in clean rooms.

- Product benefits:

- Pleasant to the touch with no annoying contour transitions in joint areas

- Time savings when assembling thanks to simple plug-in principle - no sawing, welding or painting

- No subsequent surface coating required

- Suitable for space-saving transportation thanks to extremely simple assembly/disassembly

- Reusable components - system is easy to modify

- Individual components and complete systems available

The constructional elements of the industrial stairs and working platform system include tubes, numerous tube connection variants, panels, step profiles, side plates and the corresponding mounts and rails. The material used is a corrosion-resistant and easy-to-clean aluminium. The treading surface of the step profile, which is also suitable for

implementation of platform surfaces, complies with DIN EN ISO 14122-3 and accident prevention regulation (UVV) DIN 24530.

Click now to receive more information:

ITAS catalogue Online product finderTube connectors for industrial staircases, railings and working platforms – PLAN AND ASSEMBLE ...IT'S AS SIMPLE AS THAT!

Standardised tube connectors and the available 3D datasets make ITAS superstructures and system railings very easy to design and assemble, without any machining whatsoever. Although the assembly time required depends on the complexity of the construction, it is still considerably shorter than with welded steel structures.

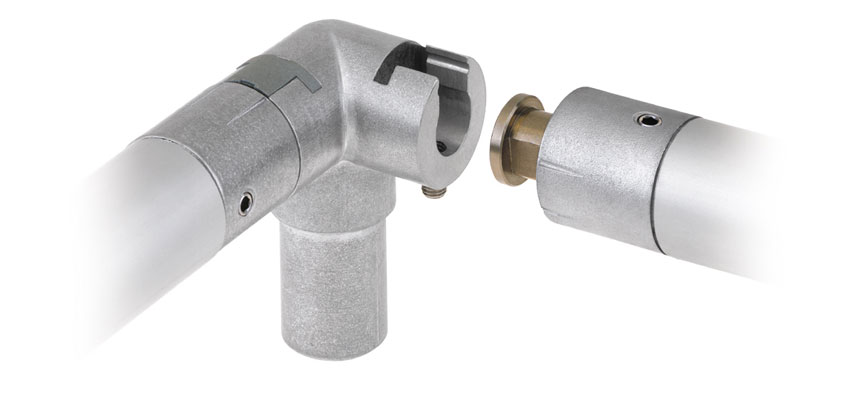

In addition, the ITAS internal clamping system for tube constructions makes installation easier. Without no machining whatsoever, tightening a single screw is all it takes to quickly secure the tube construction.

The geometry of the ITAS elements makes for a secure fit. Extremely convenient: Complex constructions can be dismantled into segments for convenience of transportation or maintenance work.

The ITAS tube connection system is successfully used in many industries. The standard elements, for instance, can be modified so that they also meet the high demands of clean rooms.

- For your safety: The system not only meets the safety requirements as per DIN EN ISO 141221-4, but also features further convenient properties. These include smooth contours and internal clamp connections, which allow the tubes and profiles to be connected to each other without any undesirable transitions. This makes for a pleasant feel, and also prevents gloves or work clothing from catching, thus contributing to user safety.

At the same time, the smooth contours make it easier to clean the individual ITAS elements and modules before entering clean rooms or hygiene-sensitive production areas.

Various clamping techniques for optimal use of the railing systems in industry

The inside clamping system for tube constructions

Principle: The clamping rocker is tilted by screwing in the set screw. The other end of the clamping rocker pushes the thrust piece against the inside of the tube. Without any machining whatsoever, the tube construction is quickly secured by simply tightening a screw.

The inside clamping system offers a technically reliable solution for installing railings, fences, pedestals, stairs, crossovers and working platforms of all kinds. The transitions between the inside clamping components and the connection tube are smooth and comfortable for the hands. No finishing required!

Quick change principle (SWS)

The quick change system for tube construction

Work and machine areas which in the past required additional guards can now be made accessible in an instant and without using any tools, thanks to the ITAS quick change system for industrial railings. This makes the laborious removal of entire rail segments a thing of the past.

The quick change system unites the combinability of the inside clamping system with simple assembly and disassembly of elements compared to conventional railing systems. Work and machine areas that previously required laborious additional securing can now be directly integrated into the planning of the ITAS system.

Stair platform

Working platform

Railings and handrails

Always the right contact

Your contact at RK ROSE+KRIEGER:

Olaf Durstewitz

Head of Product Consultancy