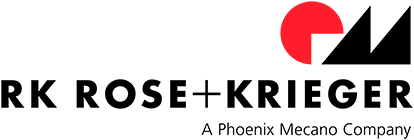

The new member of the RK Monoline product line is based on the roller guide concept of the RK MonoLine Z 80, but has a different drive concept: on the RK Monline MT, the timing belt does not circulate, but is driven in the area of the guide carriage. That is why an Omega drive is referred to. The tried-and-tested variable mounting concept allows the motor position to be changed subsequently for almost all motors available on the market. Compact dimensions facilitate high speeds and high positioning accuracy and repeatability – in particular for use as a vertical axis in a multi-axis system with travelling base profile and stationary carriage/motor. As a horizontal axis with a rated load on the carriage, on the other hand, extremely long strokes can be achieved. A further typical application is use as a moving axis.

- Product benefits:

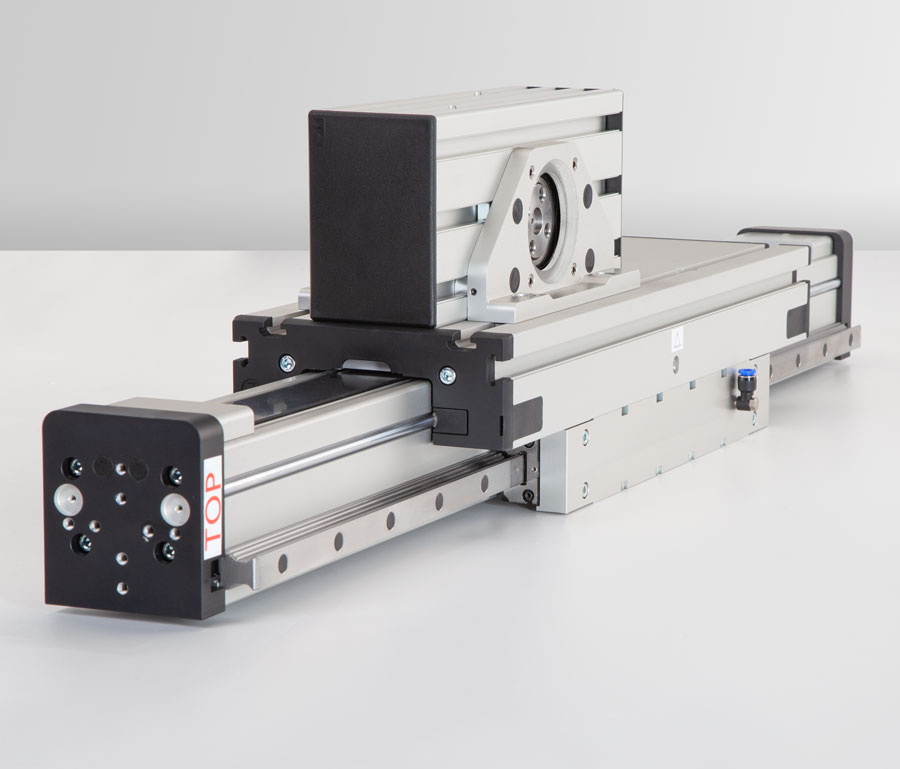

- Optional long guide carriage – higher load/torque capacity and rigidity

- Variable motor connection which can still be modified subsequently

- Central lubricating access on the carriage facilitates maintenance

- Centring holes in the guide carriage and end elements reduce the required assembly/alignment work

- Optionally integrated locking system to secure the load for vertical arrangement

- Sizes 80, 80x120, 80x160

Variable mounting system

As with the timing-belt-driven linear units in the RK DuoLine range, the RK MonoLine Z also features a variable mounting system for almost all motors available on the market. The motor position no longer needs to be specified when placing an order and can be changed at a later stage. The new actuators are fitted with a timing-belt guidance system as standard. The optional clamping and slot stone bars reduce the amount of engineering required and make customisation easier. The profile slots enable maximum flexibility for the fixation of customer-specific accessories, such as drag chains and tube holders, as well as limit or proximity switches for limit switching. The payload is fixed securely using the slot stones with tapped holes available as accessories. For users this means minimal effort required in construction, reduced assembly costs and quicker assembly. Special tapered lubrication nipples on the side of the carriage facilitate lubrication of the linear units in any carriage position. It is not necessary to move the units into a particular maintenance position or to disassemble any fittings. Central lubrication speeds up maintenance and also makes it safer and simpler. The new linear actuators impress due to their smooth running and high precision when subjected to medium dynamic loads.

Always the right contact

Your contact at RK ROSE+KRIEGER:

Olaf Durstewitz

Head of Product Consultancy