A simple workbench, height-adjustable, as LEAN workstation, with or without assistance system – designed to suit your task

A human being is indispensable for many production processes. RK Rose+Krieger supplies assembly workstations which are tailored to specific demands and ergonomic considerations and can also be integrated into digital production environments as required. Not every production process can be automated in a practical manner. This applies above all to the manufacturing of complex products in small quantities with a high variability and working sequences and special solutions which cannot be automated in a practical manner. In order to be able to manufacture these kinds of products and perform these kinds of sequences efficiently, special assembly workstations which can be integrated into the digital working environment, are required. The demands made of such digitisable manual workstations are high. They not only have to relieve the employee of physically demanding or monotonous tasks, but also have to help to ensure that the working sequences in question are implemented safely and flawlessly. Moreover, the reliability of assembly also has to be guaranteed in the event of an employee change – a particularly critical factor when it comes to quality assurance.

You can configure our RK Easywork standard table individually online, download the CAD data and send a direct request for a quotation as required. Give it a try!

More options with modern assembly workstations

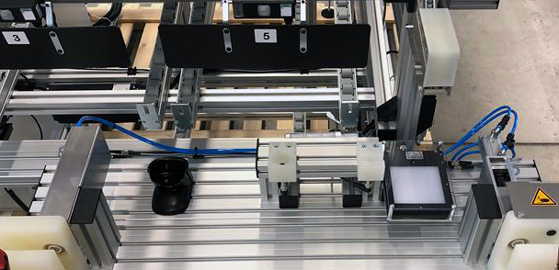

It is clear that assembly workstations nowadays no longer have much in common with the inflexible standard workstations of the past. Modern manual workstations are height-adjustable and can be adapted to the reach of the respective worker, thus ensuring ergonomic and even disabled-accessible working. The cost-efficiency of these workstations is ensured because they adapt variably to the respective tasks and can be converted in a straightforward manner for new purposes. When combined with (partially) automated removal and loading devices, such as the SETAGO pick to light system or the poka-yoke system, they also guarantee reliable, flawless production processes. These kinds of assembly workstations can of course be designed to be suitable for ESD and/or cleanrooms, and be combined with collaborative robots.

Their configuration is as sophisticated as the requirements for digitalised, ergonomic manual workstations. It can therefore prove more time- and cost-efficient to turn to an expert like RK Rose+Krieger when it comes to designing a suitable workstation, rather than attempting to put together all the elements yourself. After all, it requires comprehensive knowledge in the fields of mechanics, electronics and software solutions in order to realise an assembly workstation for safe and reliable processes and machines. Furthermore, an experienced supplier like RK Rose+Krieger not only supplies a workstation produced for the specific demands, but also provides comprehensive documentation and guarantees assured quality.

Broad range of supported assistance systems

The workstations can be equipped with various assistance modules in the interest of product quality. Alongside the aforementioned Mitsubishi poka-yoke system, these include the SETAGO pick to light system, projectors or assistance systems with intelligent image detection.

A pick to light picker, for example, ensures that the worker always assembles the correct components in the right order. In the process, the sensor solution helps him or her by indicating the component which has to be picked at any given time and automatically signalling when picking has been performed correctly. The poka-yoke system uses flap control in the interest of defect prevention. In the process, a shutter on the respective material box opens in addition to the light signal. This ensures that the worker can only select the right part for the assembly task and in the correct order. The checkback signal can be provided either automatically or manually. A sheltered workshop, for instance, is a typical area of application for poka-yoke systems.

The cognitive assistance system supports the worker with intelligent image detection and processing. It guides him or her through the individual assembly steps, checks the position of parts and that assembly is performed correctly, indicates defects and thus actively assures the quality of the manufactured assemblies. The projector is a further visual aid. It visualises the type and position of the parts and the assembly sequence for the employee using light signals, and is therefore suitable, not only for everyday use, but also for training courses and for introductory training for new employees.

Assembly workstations can be equipped with small collaborative robots, also referred to as cobots, specifically to relieve the worker of monotonous, physically strenuous or dangerous tasks. They work together with the human, hand him or her material, for example, or deposit finished parts. They are steered manually in the "teach-in" in order to learn these working steps. Once the process has been learned, the cobot then performs it automatically. This way, even critical or dangerous processes can be automated using cobots and thus the risk to employees is eradicated or at least minimised.

Always the right contact

Your contact at RK ROSE+KRIEGER:

Olaf Durstewitz

Head of Product Consultancy

![[Translate to Englisch:] [Translate to English (UK):] RK Easwork Arbeitstische - höhenverstellbar oder statisch [Translate to Englisch:] [Translate to English (UK):] RK Easwork Arbeitstische - höhenverstellbar oder statisch](/fileadmin/images/rk/produkte/modultechnik/arbeitstische/easywork/Teaser_RKEasywork-Arbeitstische.jpg)

![[Translate to Englisch:] [Translate to English (UK):] Lean-Arbeitsplatz [Translate to Englisch:] [Translate to English (UK):] Lean-Arbeitsplatz](/fileadmin/images/rk/produkte/modultechnik/arbeitstische/lean-arbeitstische/Teaser-Lean-Arbeitsplatz.jpg)

![[Translate to Englisch:] [Translate to English (UK):] Pick-to-Light Arbeitsplatz [Translate to Englisch:] [Translate to English (UK):] Pick-to-Light Arbeitsplatz](/fileadmin/images/rk/produkte/modultechnik/arbeitstische/setago/Teaser_Pick-to-Light_Arbeitsplatz.jpg)

![[Translate to Englisch:] [Translate to English (UK):] Poka Yoke Arbeitsplatz [Translate to Englisch:] [Translate to English (UK):] Poka Yoke Arbeitsplatz](/fileadmin/images/rk-rose-krieger/produkte/modultechnik/pokayoke/Teaser-PokaYoke-Arbeitsplatz.jpg)

![[Translate to Englisch:] [Translate to English (UK):] Cobot-Arbeitsplatz [Translate to Englisch:] [Translate to English (UK):] Cobot-Arbeitsplatz](/fileadmin/images/rk-rose-krieger/produkte/modultechnik/cobot/Teaser-Cobot-Arbeitsplatz.jpg)

![[Translate to Englisch:] [Translate to English (UK):] Materialwagen, Transportwagen, Lagergestelle [Translate to Englisch:] [Translate to English (UK):] Materialwagen, Transportwagen, Lagergestelle](/fileadmin/images/rk/produkte/modultechnik/arbeitstische/intralogistik/Teaser-Materialwagen.jpg)

![[Translate to Englisch:] [Translate to English (UK):] RK Lean Workshops [Translate to Englisch:] [Translate to English (UK):] RK Lean Workshops](/fileadmin/images/rk/service/lean-workshop/Teaser-Lean-Workshop.jpg)