Applications in actual practice

Production process (value creation)

Height-adjustable workstations on the assembly line

Working height needs to be optimally adapted to suit the height of the operator and the dimensions of the product. Height-adjustable workstation systems from RK Rose+Krieger enable ergonomic optimisation and thus minimise physical strain.One-Piece-Flow

Production processes are arranged section by section in so-called islands. Where the operator changes frequently (e.g. in shift operation), individual adjustment of the working height makes good ergonomic sense and increases productivity.With the RK modular system, every workstation can be optimally configured

An optimally configured workstation should adapt to conditions and requirements, and not only from an ergonomic perspective – workflow should also be considered. With the RK modular system, almost any workstation design can be realised and subsequent extensions or modifications can be easily implemented.A workstation should be optimally configured for the specific task in hand

Dynamic and fatigue-free working demands an optimally configured workstation. The quality of work increases, processing times are cut, absences due to illness are reduced. Each workstation is configured exactly according to your specifications and requirements.Mobile, rotatable and height-adjustable measuring table

Universally adjustable tables and equipment enable flexible use and ergonomic working. Workpieces with different dimensions are easy to process and inspect.In addition to ready-to-install components, RK Rose+Krieger also offers complete systems tailored to your specifications and requirements.

Material trays – everything you need within easy reach

If tools and materials are not located exactly where you need them, production times increase!Measuring instruments, gauges and tools can be optimally positioned at your workstation thanks to additional storage and tray levels.

Transportation / Logistics

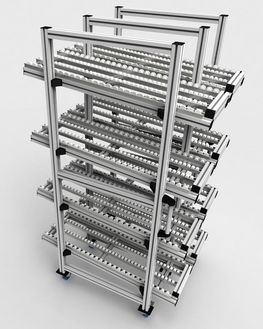

Shelving systems

LEAN shelving systems support the supermarket principle. Ergonomic and optimal positioning of the parts box guarantees that the parts can be removed quickly and easily.The shelves are on castors and can therefore be moved to the right location for assembly at any time.

Transport trolley and transport shelves

Using BLOCAN transport trolleys and transport shelves, components can be moved to the right location without the need for further equipment such as fork lift trucks or lifting carts. The flexible BLOCAN profile system allows quick and uncomplicated conversion for new models or components.Mobile equipment table – flexibility on the assembly line

Mobile equipment tables can be added to an assembly line wherever required or can be used to ensure an uninterrupted supply of small parts, for example.Testing units and other equipment for the production process can also be accommodated.