We provide consultation services and implement your customised system solutions

As a one-stop supplier with a wide product spectrum, RK Rose+Krieger is able to use its own modular system for the development, production and assembly of customised system applications. Tailor-made machine frames, safety guards, height-adjustable work tables and automation technology are produced using the BLOCAN® profile technology, ITAS components, RK linear technology and RK connecting technology.

- RK module technology, your benefit!

- Consultancy and design by our product specialists – our expertise at your fingertips!

- Manufacture of components

- Installation by product experts

- Complex modules from a one-stop supplier

- Our design service allows you to focus on your core competences

Based on a sketch or customer description, experienced product specialists work in close cooperation with the user to develop a complete solution which precisely meets the customer's needs – nothing more and nothing less. The applications are manufactured by product specialists at RK Rose+Krieger. Assembly on the customer's premises can be carried out by a regional system partner.

Working with a truly competent partner allows you to focus on the task in hand. We bring our extensive knowledge and experience to the table to help you make your business a success.

Virtual 3D tour “System solutions”Examples from practice:

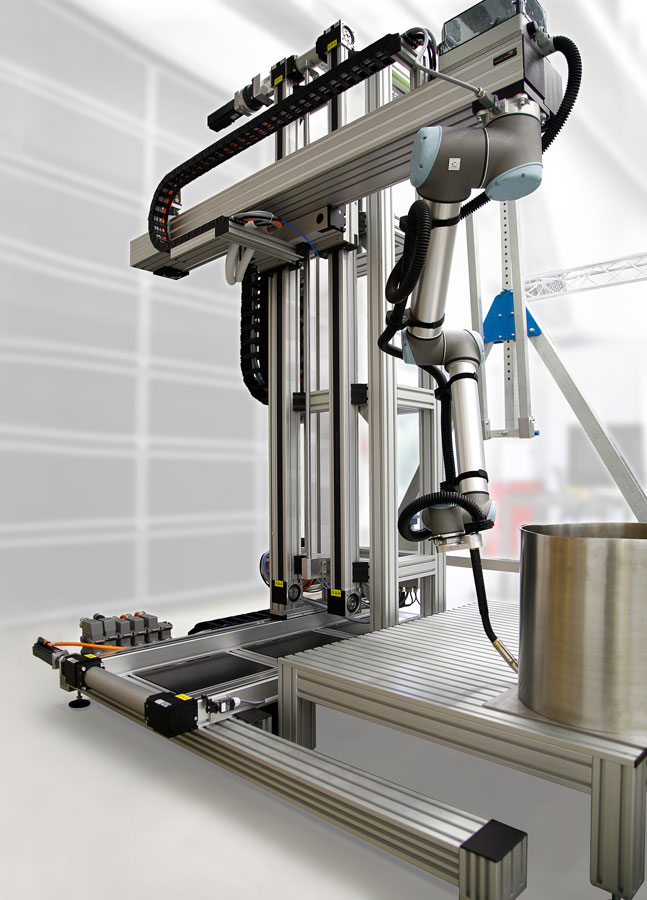

Workstation systems / assistance systems

A simple workbench, height-adjustable, as LEAN workstation, with or without assistance system – designed to suit your task

• RK Easywork workbenches

• LEAN workstation

• Pick to light workstation

• Poka-yoke workstation

• Workstation with camera-based assistance system

• Assembly workstations with COBOT connection

• Transport/material/assembly trolley

Machine frames

• Frames for machinery, systems, equipment and many more.

• A flexible aluminium profile system ensures a stable and adaptable base frame for your system

• Simple connection of machine components via profile slots

• Additional optional extras available (milled slots, holders, adapters)

• Compatible with RK tube connectors and linear units

Ergonomic assembly fixtures

We offer you individually adapted assembly fixtures that optimally support your work processes. In addition, ergonomic and adapted work ensures more mobility and less downtime for the employee.

• Jigs and fixtures for manufacturing, jig and fixture construction and much more.

• Ergonomic and fatigue-free work

• Basic frames from the BLOCAN profile system, individually designable and extendable

• Adjustment of inclination and height by lifting columns or electric cylinders

• Mobile solutions with powerful battery controls

ITAS – industrial stairs and working platforms

• Individual adaptation of working platform to a specific machine according to customer specifications

• A flexible railing system allows easy adaptation to changing requirements

• Treadway surfaces selected according to customer specification and combined with standard RK components

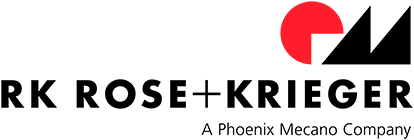

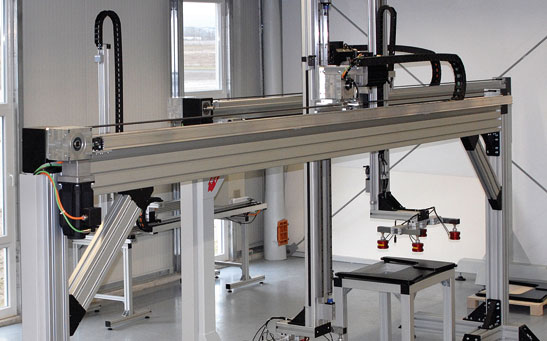

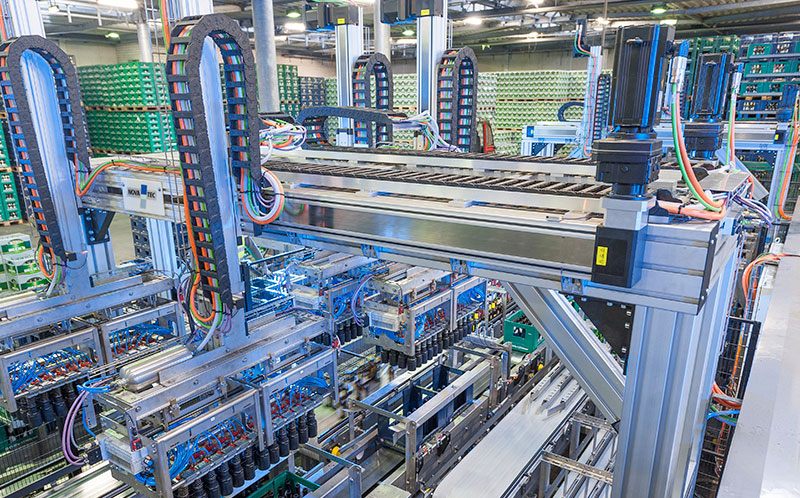

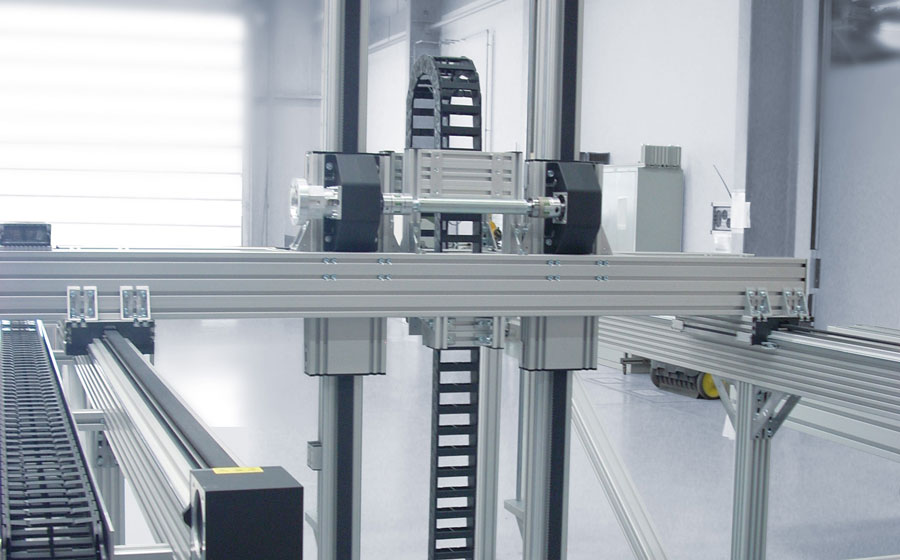

Multiple axis handling system with protective housing

• 3-axis handling system comprising more than 80% RK components

• Design of linear components (linear actuators, controls, motors, adapters) by RK technicians

• Base frame from the BLOCAN profile system

• Subsequent ring-fencing of danger zone using the RK safety guard system

Machine housing

Design, drawings, engineering of special elements and installation by RK Rose+Krieger

• Encapsulation of production lines and plants

• Optimum adaptation to on-site conditions thanks to flexible aluminium profile system

• Easy to dismantle panels (e.g. for maintenance work)

Always the right contact

Your contact at RK ROSE+KRIEGER:

Olaf Durstewitz

Head of Product Consultancy