New products – new possibilities

The market situation created by customer applications, cost sensibility, rising quality demands and new technical trends most often leads to new products and offers. We would surely be slower without your demands. We appreciate this very much and thank you. Please find our latest solutions as follows:

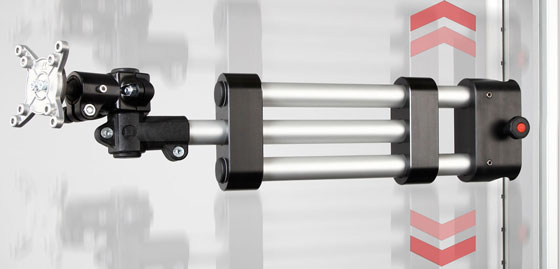

![[Translate to Englisch:] [Translate to Italienisch:] Monitorhalterungen [Translate to Englisch:] [Translate to Italienisch:] Monitorhalterungen](/fileadmin/images/rk/produkte/rohrverbindungstechnik/monitorhalter/Teaser-Monitorhalterung.jpg)

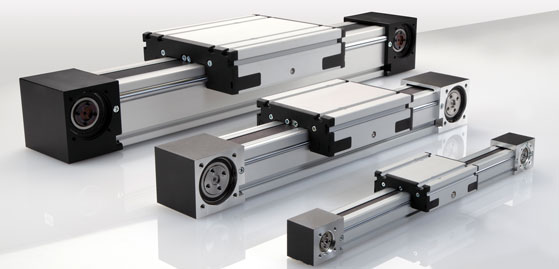

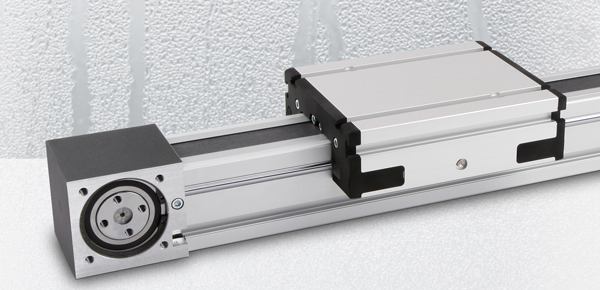

![[Translate to Englisch:] [Translate to Spanisch:] Schiebeführung RK LightUnit G / telescope [Translate to Englisch:] [Translate to Spanisch:] Schiebeführung RK LightUnit G / telescope](/fileadmin/images/rk/aktuelles/produktneuheiten/lineareinheiten/lightunit-g/Teaser-LightUnit-G-Schiebefuehrung.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/images/rk/aktuelles/produktneuheiten/lineareinheiten/epx/Teaser-EPX-II.jpg)

![[Translate to Englisch:] [Translate to Italienisch:] Steuerung MultiControl II duo accu [Translate to Englisch:] [Translate to Italienisch:] Steuerung MultiControl II duo accu](/fileadmin/images/rk/produkte/lineartechnik/steuerungstechnik/akku/Teaser-MC-Akku.jpg)

![[Translate to Englisch:] Edelstahl-Montagesystem [Translate to Englisch:] Edelstahl-Montagesystem](/fileadmin/images/rk/produkte/rohrverbindungstechnik/ems/Teaser-EMS.jpg)

![[Translate to Englisch:] [Translate to Italienisch:] Rohrverbinder WER 30 aus Kunststoff [Translate to Englisch:] [Translate to Italienisch:] Rohrverbinder WER 30 aus Kunststoff](/fileadmin/images/rk/aktuelles/produktneuheiten/rohrverbinder/Teaser-Rohrverbinder-WER30.jpg)

![[Translate to Englisch:] RK Mehrachsbaukasten [Translate to Englisch:] RK Mehrachsbaukasten](/fileadmin/images/rk/produkte/lineartechnik/mehrachsbaukasten/Teaser-Mehrachsbaukasten.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/images/rk/produkte/rohrverbindungstechnik/itas/Teaser-ITAS-verstellbar.jpg)

![[Translate to Englisch:] RKX Software [Translate to Englisch:] RKX Software](/fileadmin/images/rk/produkte/lineartechnik/steuerungstechnik/Teaser-RKX.jpg)