Network-independent synchronous control – battery operation for lifting columns and electric cylinders

With a rechargeable battery version, we are adding to our successful product range of MultiControl II controllers with a completely wireless version. The special feature is the new MultiControl II duo accu’s specially designed battery adapter for standardised batteries from well-known manufacturers. In an ideal world, users can use their existing battery systems to charge the control.

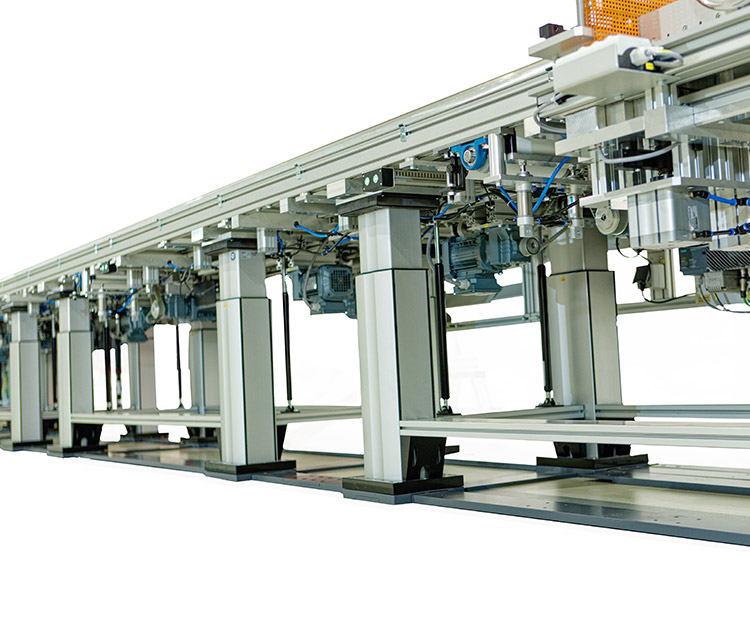

The MultiControl II duo accu is ideal for implementing mobile systems in the field of intralogistics and assembly workstations. Height-adjustable and/or tilting workshop trolleys, lifting mechanisms and workbenches can be easily moved from one production station to the next, where they can be ergonomically adjusted to the size of the worker and brought into the optimum working position. Limiting the range with cables and the associated tripping hazards are a thing of the past.

- MultiControl II duo accu product benefits

- Ready for use – No fixed pause times thanks to dynamic duty cycle calculation

- Reliable – Duty cycle, overcurrent and temperature monitoring for overload protection as standard

- Straightforward – Intuitive operation using hand switch with graphics-capable display

- Flexible – Rechargeable battery solution for location-independent ergonomics

- High-performance – Up to 150 double strokes with a single battery charge

- Efficient – Standby times of up to 15 days

- Compatible – Fully compatible with the BLOCAN product portfolio

- Upgradable – Synchronous movement of up to 16 drives

- Adaptable – We implement special applications for you with Premium Customized

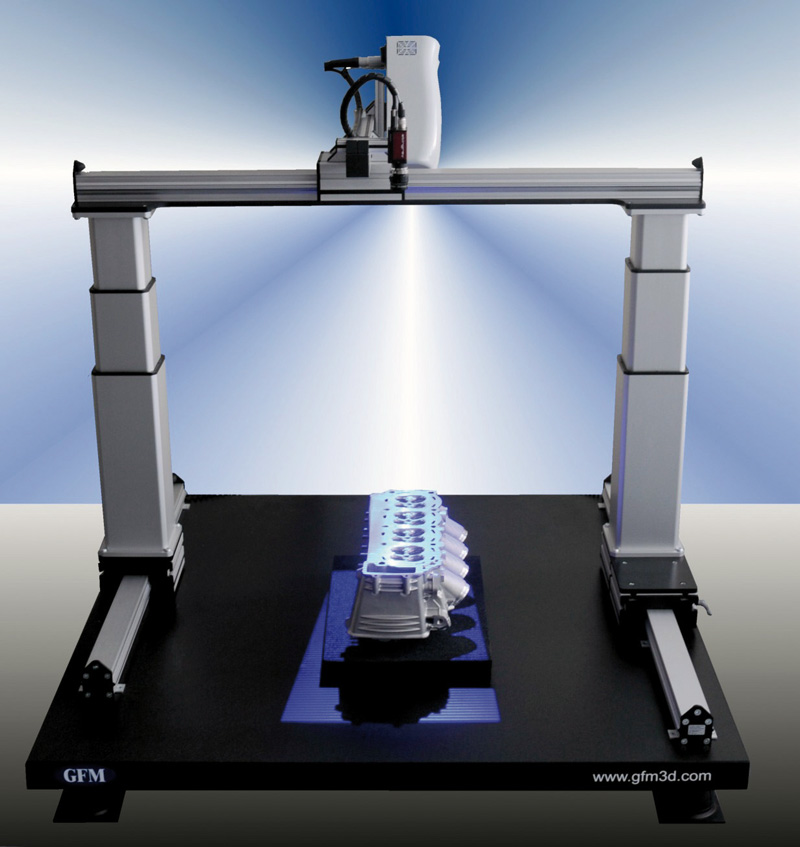

MultiControl II duo DC – control cabinet integration or movement applications in automotive engineering solved easily

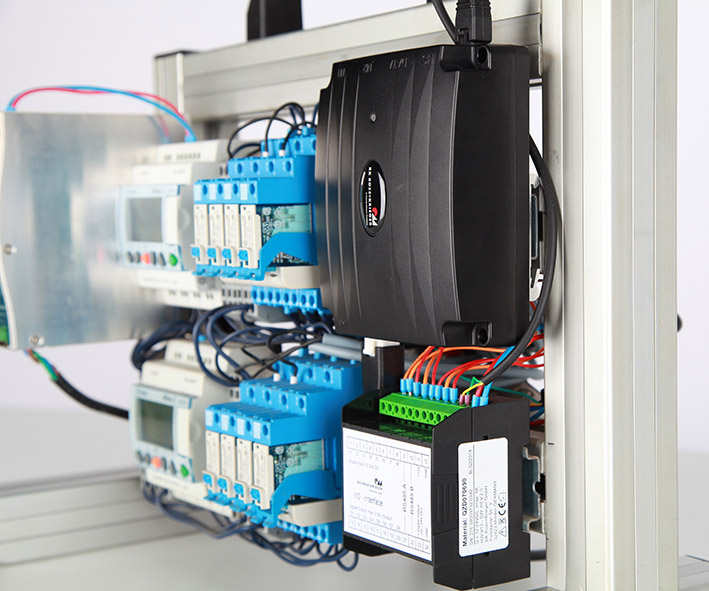

Thanks to the direct 24 V power supply and its small dimensions, the MultiControl II duo DC is ideally suitable for applications in industry or automotive engineering. Both the actual hand switches and an I/O interface can be connected as the operating interface. The I/O interface provides 16 digital inputs and outputs for control. Status messages, memory positions and encoder emulation can be implemented using the standard functions in just a few simple steps. That way, a broad range of requirements can be catered for with just the standard components, in particular in combination with the lifting columns and electric cylinders.

The MultiControl control can be easily and quickly integrated into a control cabinet via an optionally available top hat rail adapter.

Complete range of functions with battery operation as well

The battery-operated version of the synchronous control has the same range of functions as the wired models. Like these, the MultiControl II duo accu can also be combined to form larger systems with up to eight controllers or 16 drives, thus allowing the implementation of complex mobile systems or particularly high-performance requirements. In larger systems, the master control system continuously monitors the battery charge status of the individual controllers. Discharged batteries can thus be identified directly and without a long search.

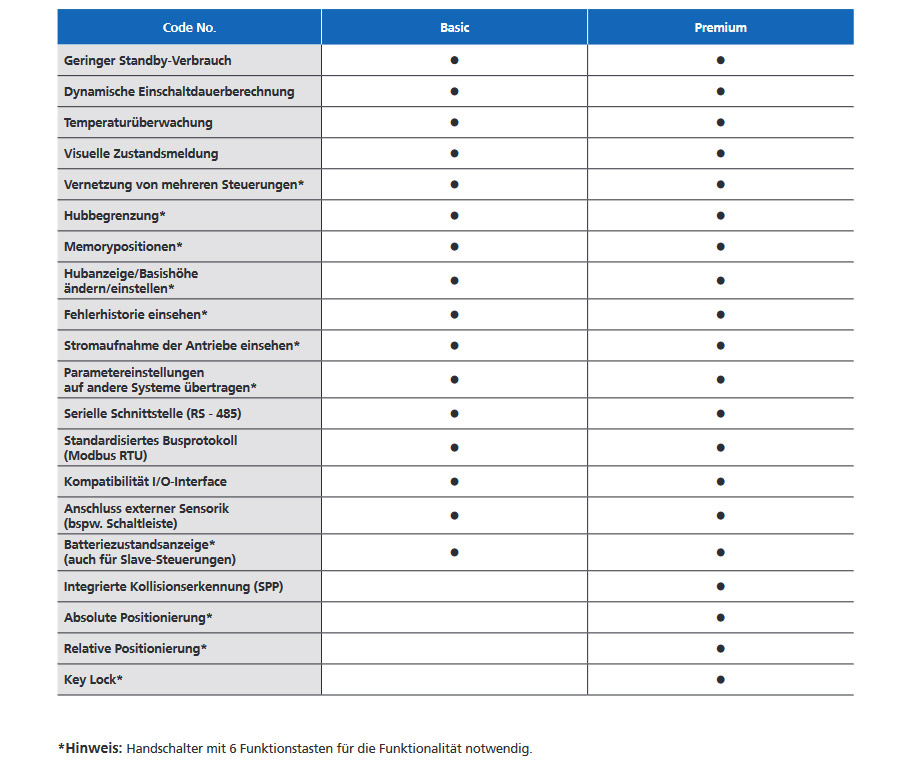

Like the wired version of the MultiControl II duo, the new control is also available in a Basic and a Premium version with additional software functions.

The MultiControl II duo accu is operated intuitively via a hand switch with graphics-capable design. The standby consumption of the energy-efficient overall system consisting of control and hand switch is less than one watt. For connection to master control system levels, the wireless control has the RS-485 serial interface and the standardised Modbus RTU protocol. Standard monitoring of duty cycle, overcurrent and temperature protects them from overload.

Extensive accessories for even more comfort

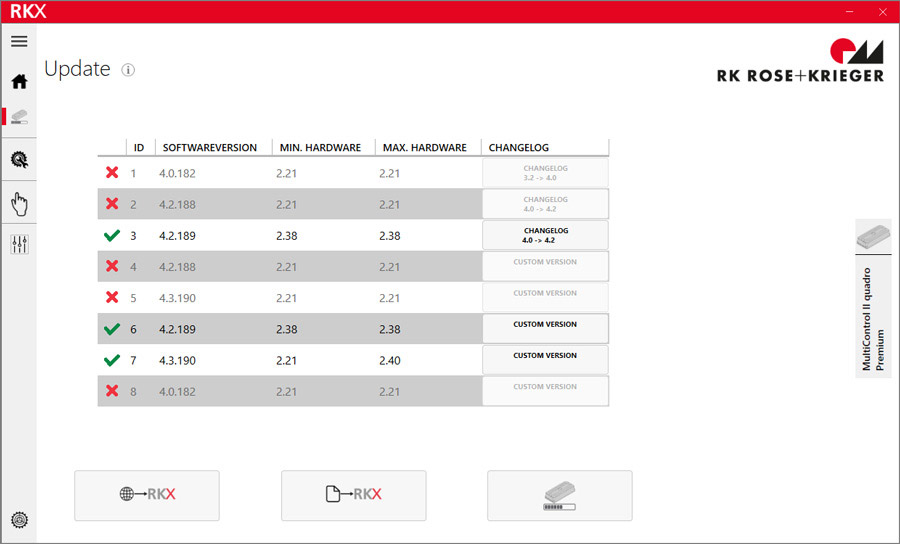

In addition to the RKX software with its multitude of interaction options and functions, the wireless control accessories also include an I/O interface for controlling the MultiControl II duo accu via digital inputs and outputs of a PLC. Also available are various cables for interconnecting the battery and control as well as several controls with each other, hand switches with two or six function keys and a hand switch drawer, as well as a foot switch with two function keys and the matching adapter cable.

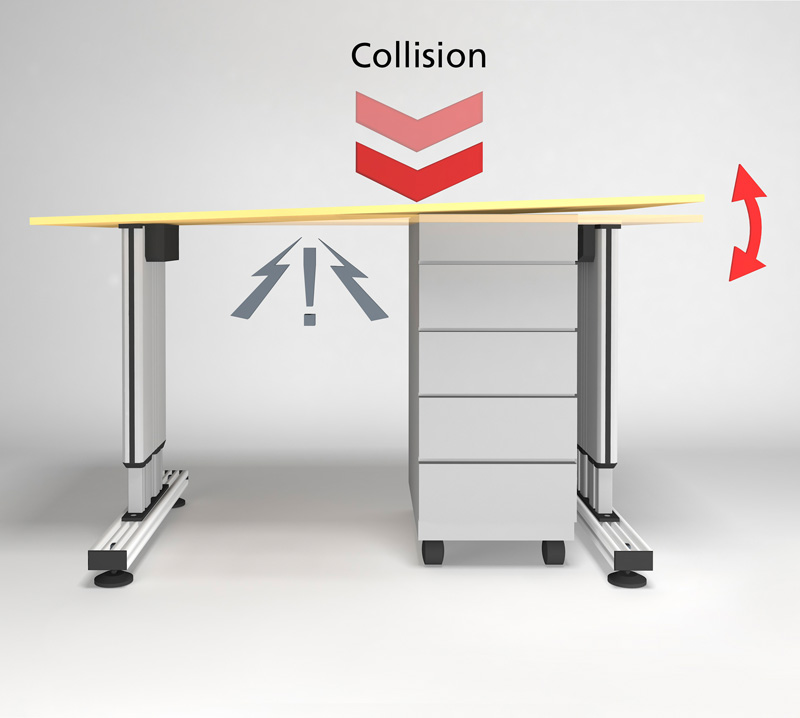

SPP – Smart Product Protection (integrated collision detection)

The Premium version of the MultiControl II unit incorporates RK Rose+Krieger GmbH’s proprietary SPP technology. This technology considerably reduces the risk of product damage in the customer’s application. Protection is provided not just for the connected drives, but also for the adjoining set-up as a whole.

When adjusting the height of tables or machine frames, for instance, there is a latent risk of collisions as a result of raising and lowering a load. If such collisions occur, they can cause damage to drives (reduced service life and the possibility of complete failure) but also the adjoining set-up, or may cause obstructions.

SPP is a software-based solution for collision detection. A major benefit is that the technology is fully integrated into the control system, which means that the customer application does not need to be equipped with any additional external sensors.

A further special feature is that the customer is able to adjust the sensitivity of the system (actuation force when a collision is detected) to suit the specific application. The key advantages of integrated collision detection are summarised below.

Relative and absolute positioning

Alongside the integrated collision detection (SPP), the Premium version has two further functions which relate to the type of drive positioning.

In addition to approaching previously stored memory positions, relative or absolute positioning can now be carried out too. The first of these enables positioning relative to the current position of the lifting column. The operator control can thus be used to set a defined value (e.g. 30% or 30 mm) by which the drive further retracts or extends.

Absolute positioning, on the other hand, utilises the complete scale of the adjustment range. So the operator control can also be used to move the drive precisely to a predefined position. This function can be very important for applications in which components are measured, for example.

Always the right contact

Your contact at RK ROSE+KRIEGER:

Olaf Durstewitz

Head of Product Consultancy