Linear units, electric cylinders and lifting columns from RK – Your solution is included

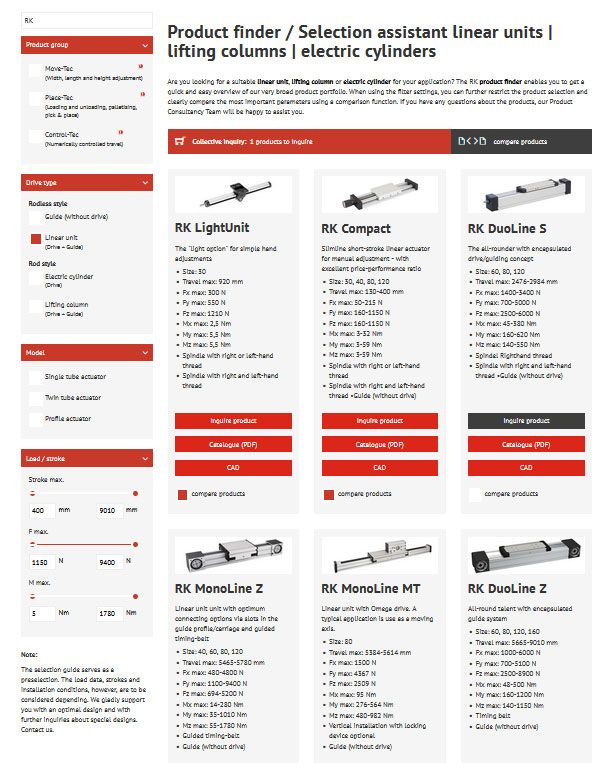

Whether guiding, adjusting, positioning or moving uniformly, the demands on linear motion sequences are as varied as the available solutions. The linear technology comprises a broad range of linear units: from single or twin-tube units for simple manual operation and occasional use to automatic profile axes for frequent movement and highly dynamic positioning systems for constant use. The linear technology range also includes electrical lifting columns for height adjustment on work benches, control stations, devices and medical equipment. Electric cylinders in various sizes and designs, as an alternative to pneumatic cylinders, round off the linear technology range.

Find the right product quickly and easily

Use our online product finder to compare linear units, lifting columns and electric cylinders. Receive catalogue and CAD data, or enquire about the specific product you require.

Go to the RK product finder for linear technology here:

Online Product finderFor more information, please select a product area:

Always the right contact

Your contact at RK ROSE+KRIEGER:

Olaf Durstewitz

Head of Product Consultancy

![[Translate to Englisch:] [Translate to English (UK):] Lineareinheiten [Translate to Englisch:] [Translate to English (UK):] Lineareinheiten](/fileadmin/images/rk/produkte/lineartechnik/lineareinheiten/Teaser_Lineareinheiten.jpg)

![[Translate to Englisch:] [Translate to English (UK):] Elektrozylinder [Translate to Englisch:] [Translate to English (UK):] Elektrozylinder](/fileadmin/images/rk/produkte/lineartechnik/elektrozylinder/Teaser_Elektrozylinder.jpg)

![[Translate to Englisch:] [Translate to English (UK):] Hubsäulen [Translate to Englisch:] [Translate to English (UK):] Hubsäulen](/fileadmin/images/rk/produkte/lineartechnik/hubsaeulen/Teaser_Hubsaeulen.jpg)

![[Translate to Englisch:] [Translate to English (UK):] Steuerungstechnik [Translate to Englisch:] [Translate to English (UK):] Steuerungstechnik](/fileadmin/images/rk/produkte/lineartechnik/steuerungstechnik/Teaser-Steuerungstechnik.jpg)